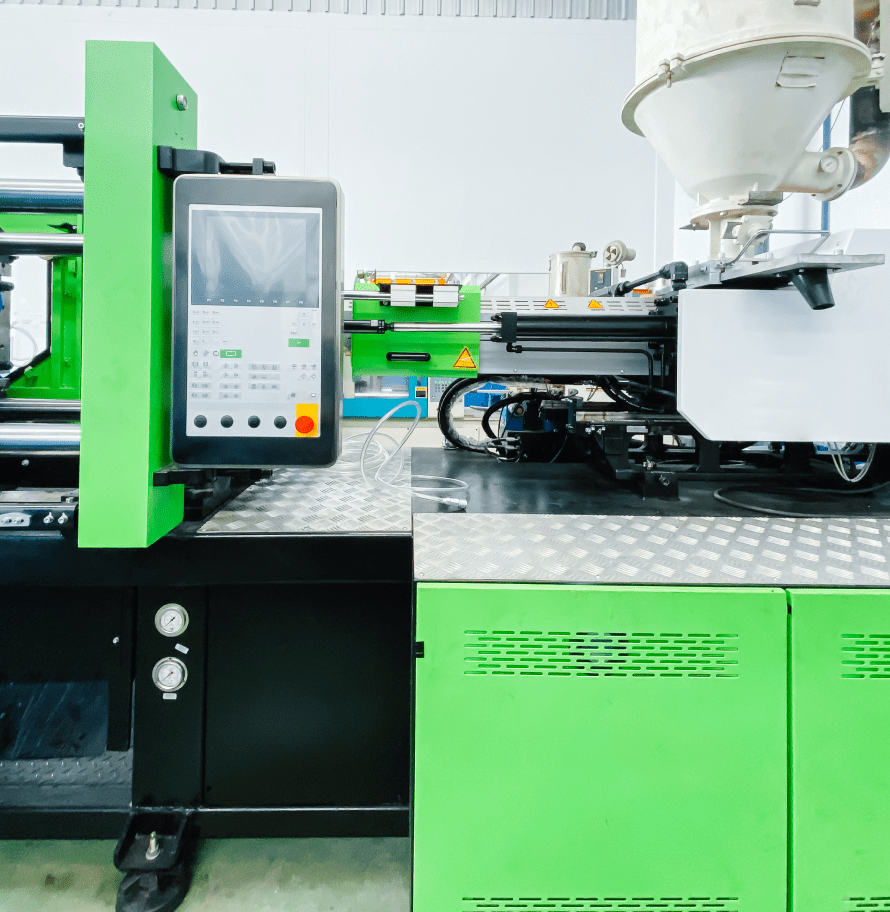

Custom Plastic Molding Solutions

Mountain Mold & Die specializes in high-quality, acetal injection molding. Our precision-driven approach ensures optimal tooling and manufacturing for your unique project needs.

Understanding Tooling for Molding

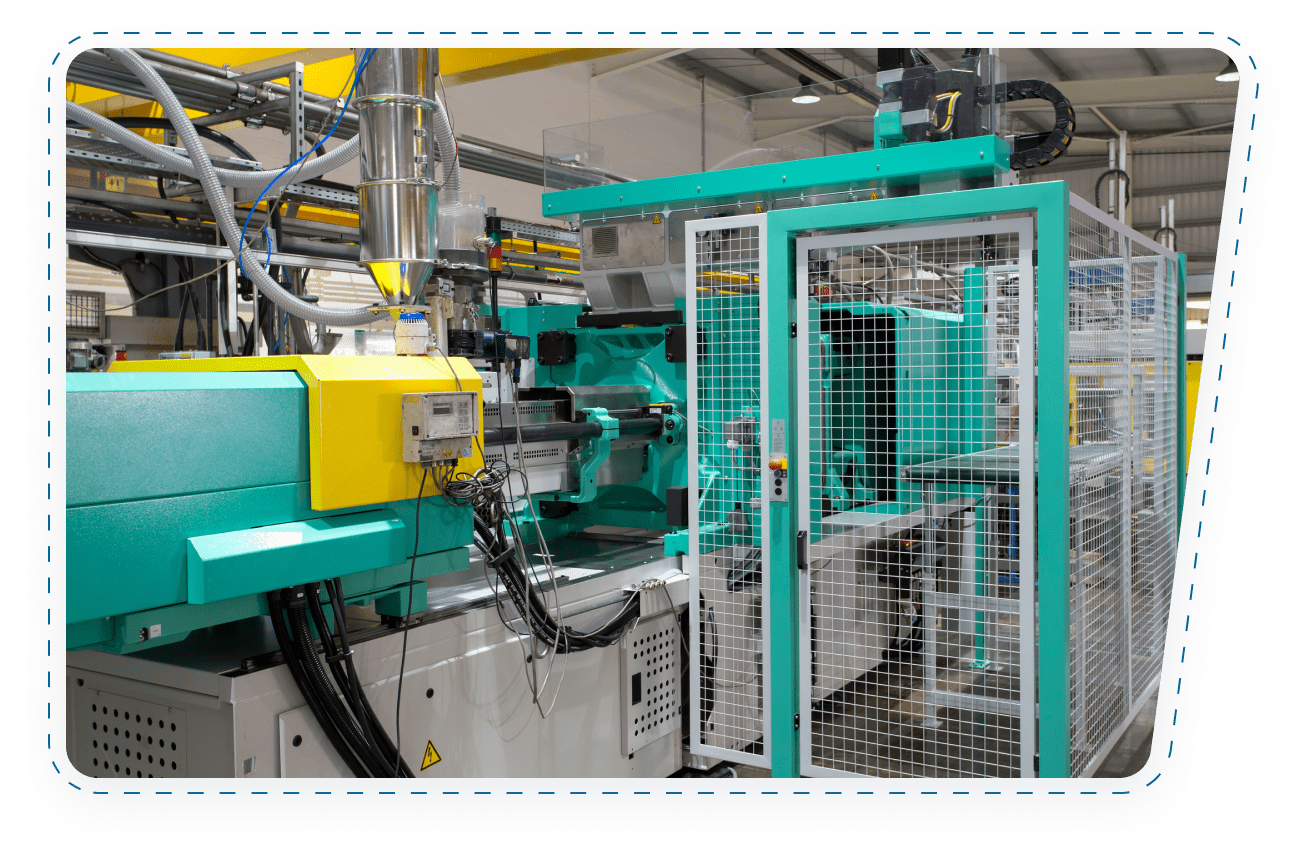

To determine the right tooling for your plastic part, including for Nylon injection molding, it’s essential to know the estimated annual usage (EAU). For simple geometries, parts with an EAU of 10,000 or more are viable, while more complex designs require 50,000+ or even millions in some cases. Custom injection molding typically involves presses with capacities ranging from 50 to 250 tons, with an EAU of 100,000+ being common. Well-maintained molds can produce consistently accurate parts for over 10 years, even for intricate designs, with low-cost mass production possible when molds are properly constructed. Materials like glass fiber reinforced plastics may require specialized tool steel inserts for durability.

Get Started on Your Project

Ready to start your custom injection molding project? Browse our range of services and find the perfect solution for your needs.