Custom Plastic Injection Molding Solutions

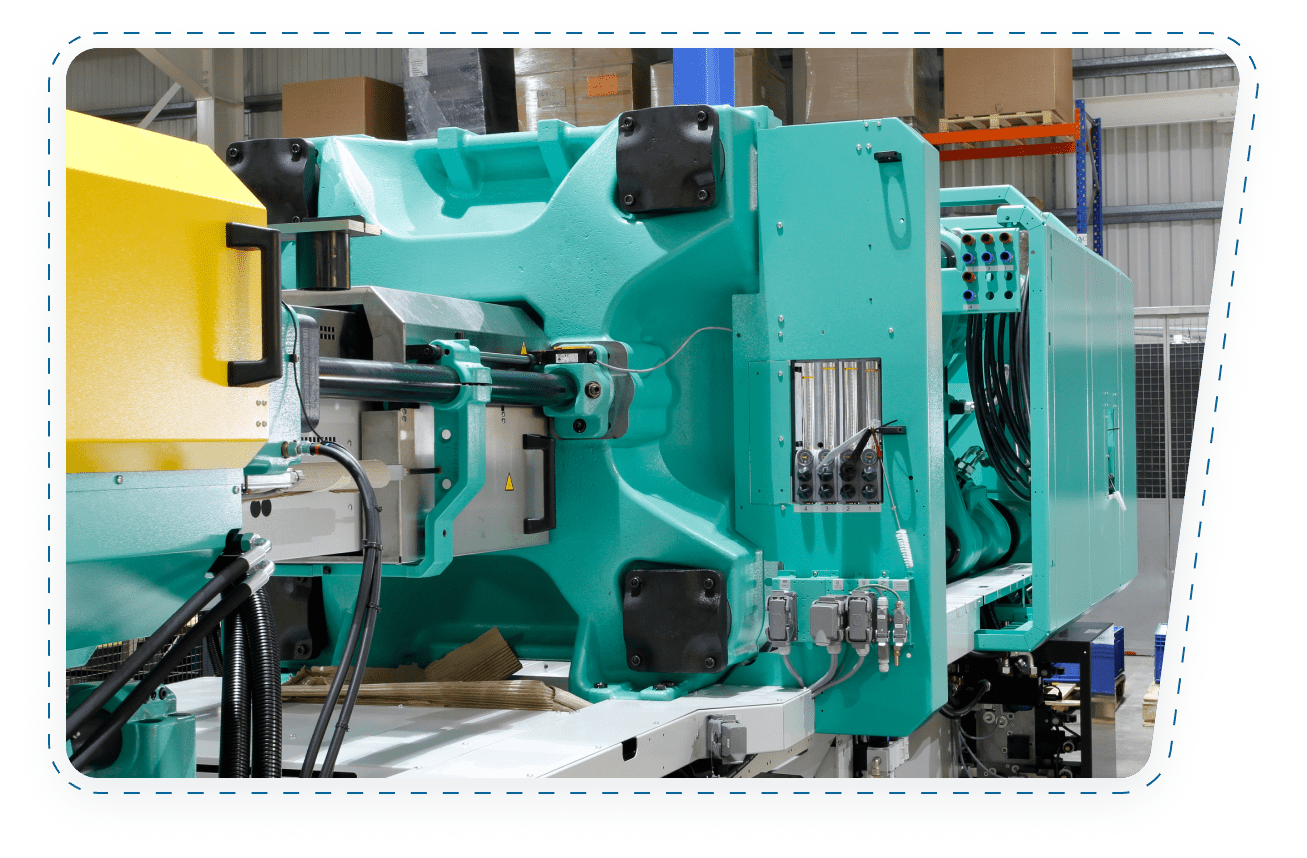

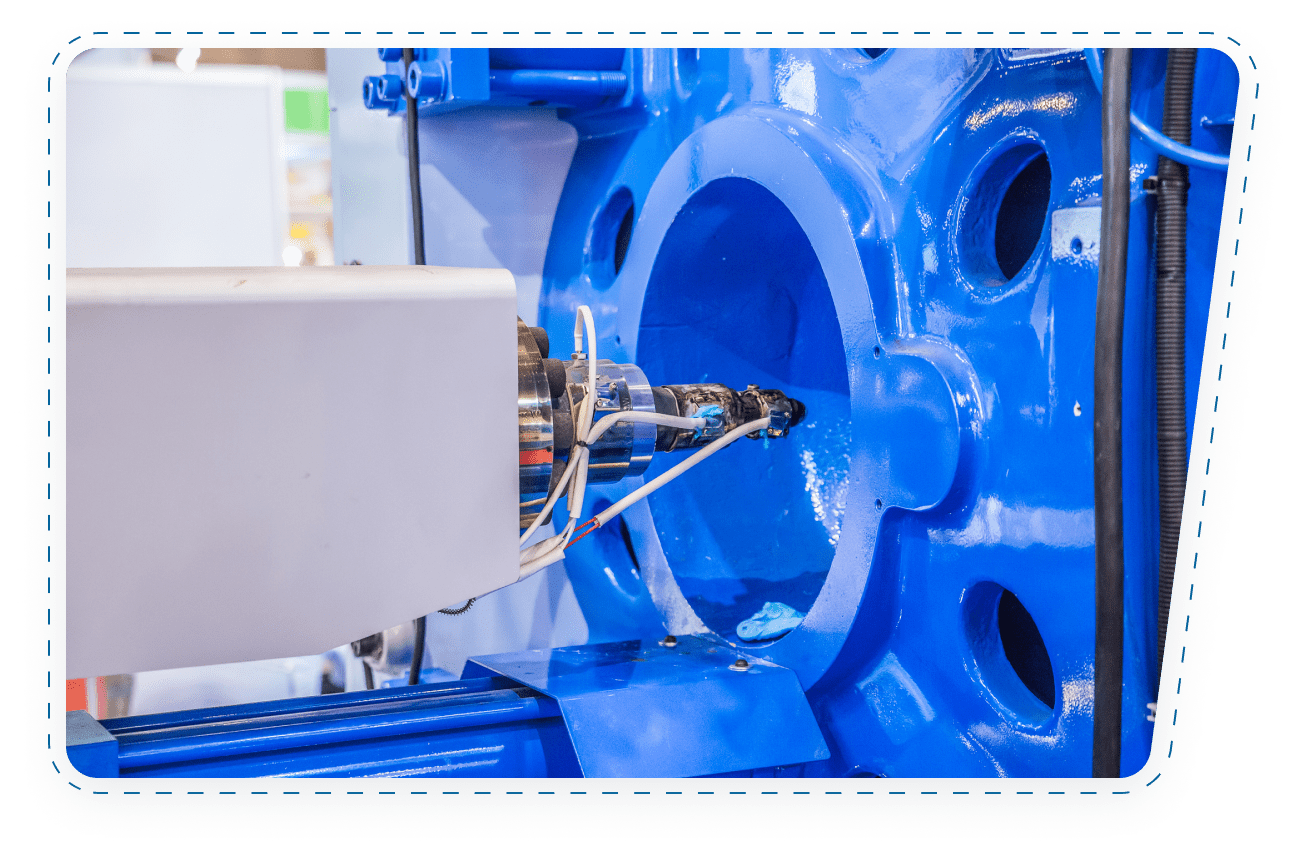

With over 39 years of experience, Mountain Mold & Die specializes in custom plastic injection molding, using a highly specialized process that includes precise material preparation, consistent machine and environmental parameters, and accurate tooling to meet part specifications. We work with a wide range of materials, including PC, ABS, PP, PE, POM-Acetal, PA-Nylon, PBT, HDPE, LDPE, TPE, TPO, TPU, and PEEK, incorporating fillers, reinforcement fibers, colorants, and property modifiers as needed. Our innovative over-molding process allows for elegant part geometry, including chemical bonding, which was previously impossible with traditional attachment methods.

Innovative Plastic Injection Molding Solutions

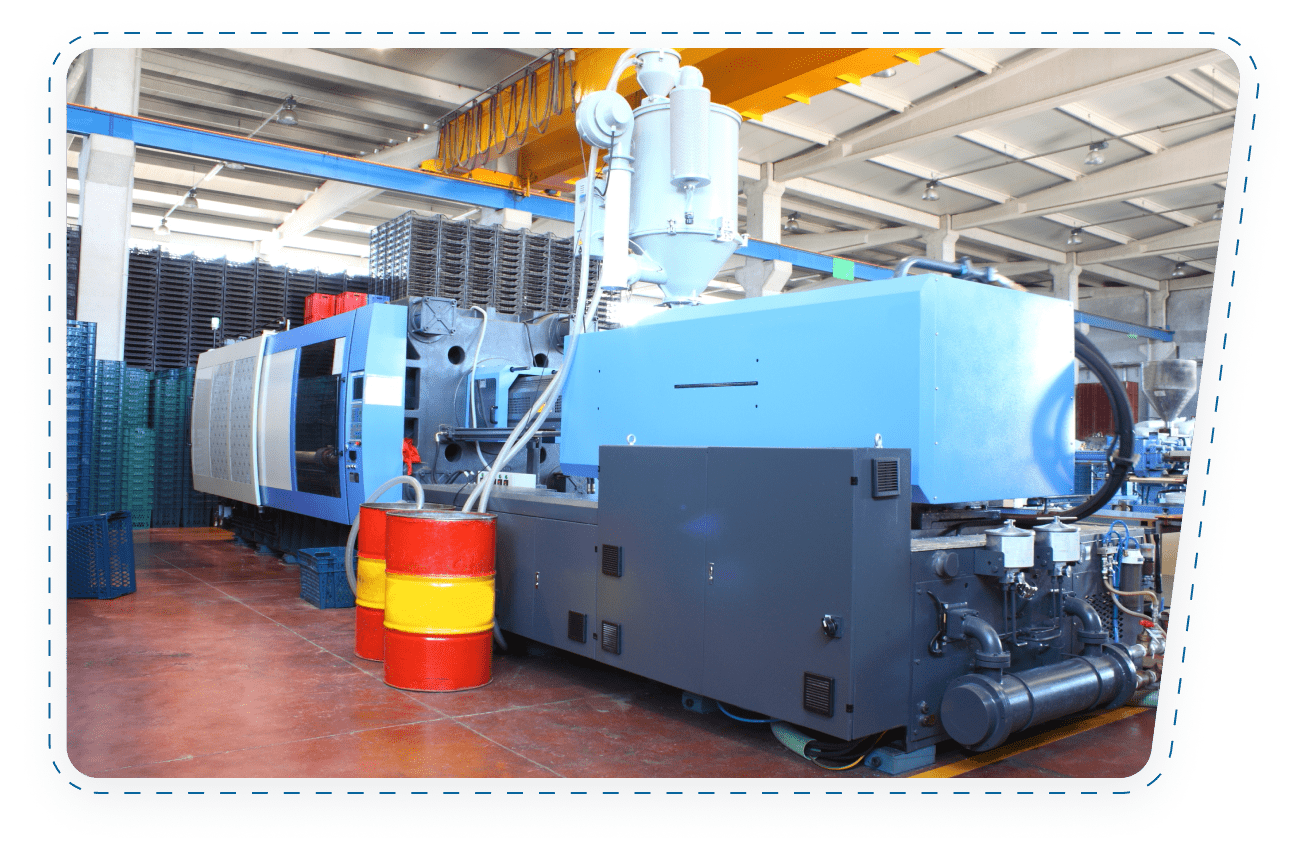

Since 1996, we've led the industry with ingenious solutions, such as over-molding glass RFID transponders in automotive keys. Our consistent process control ensures the highest quality, from machine parameters to environmental factors, maintaining the integrity of each part. We offer custom plastic injection molding services with shot capacities up to 20 oz., as well as plastic and metal insert molding and over-molding, using custom blend materials and colors. Following are the molding capacities of our equipment:

In-Mold Assembly

Many of our injection molded products, including those created through reinforced plastic injection molding, are assembled in-house, with some even being assembled directly at the press during the molding process. This seamless integration of molding and assembly is a natural evolution for custom injection molding companies. We began using innovative material properties, including chemical bonding in the over-molding process, to create elegant part geometries that were previously impossible with traditional attachment methods. Our journey started in 1996, when we developed a solution for over-molding an automotive key with an RFID transponder. Over the years, our ability to provide creative and efficient solutions has made us an industry leader in this field.

Molding Solutions for You

Ready to explore our range of plastic injection molding solutions? Whether you need custom parts, in-mold assembly, or insert overmolding, our products are designed to meet your specific needs.